We are overjoyed to extend our heartfelt congratulations to our sister company, Trisco Systems Inc., for earning the esteemed title of Walls & Ceilings Contractor of the Year 2023!

This prestigious award is a resounding testament to Trisco Systems’ unwavering dedication to industry best practices, exceptional working conditions, and the delivery of unparalleled quality workmanship and customer service.

Trisco Systems, headquartered in Lima, Ohio, is a beacon of expertise in exterior building restoration and façade rejuvenation. As their sister company, we assist with Exterior Insulation and Finish Systems (EIFS) in many projects.

Under the leadership of Steven and Brian Walter, the third generation at the helm, the company’s journey began 87 years ago. Their hands-on experience, starting from the warehouse and crews, reflects a profound understanding of the industry.

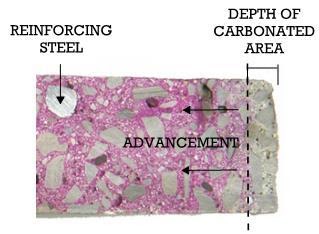

The specialized training received by Trisco Systems’ field technicians in water infiltration techniques underscores the company’s commitment to proper flashing systems, moisture control, and evacuation for building envelope success.

Beyond EIFS, Trisco’s restoration expertise spans masonry, concrete, terra cotta, and other components. As members of industry associations like the Sealant and Waterproofing Institute, the International Concrete Repair Institute, and EIMA, Trisco Systems is recognized for its unwavering commitment to industry standards.

The company’s versatility shines through in its ability to handle diverse projects, from stadiums and parking garages to water treatment plants. Maintaining quality control and efficiency, Trisco Systems’ employees travel with the company, ensuring excellence throughout the Midwest and beyond.

In the face of industry challenges, including labor and material issues, Trisco Systems has achieved controlled growth, proactively securing top talent and employing strategic purchasing to navigate successfully.

Safety is paramount at Trisco Systems, evidenced by its multiple local and national safety awards and impeccable safety record. These highlight the company’s commitment to its employees’ well-being.

As third-generation owners, Steven and Brian Walter embody dedication to preserving the company’s spirit and vision while positioning it for an even brighter future. With over 87 years of successful history, numerous customer compliments, and a commitment to financial soundness, Trisco Systems claims its place in the top tier of national contractors.

We invite you to read the full article on the Trisco Systems website for more details. Click HERE to read the full article.